| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Quanstar |

| Model Number : | |

| Certification : | ISO |

| Payment Terms : | L/C,T/T |

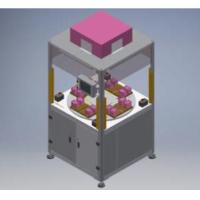

Electronic expansion valve (EVV) assembly line equipment automotive automation solution

Feeding system: Vibration trays and customized material channels

are used to transport expansion valve parts of various

specifications to the assembly area in an orderly manner. Sensor

detection is used to ensure the accurate supply of parts.

Assembly system: Multi-joint manipulators cooperate with special

fixtures to accurately grab components such as valve bodies and

valve cores for assembly. Force sensors and displacement sensors

are set up at key assembly stations to monitor the pressure and

position during the assembly process in real time to ensure

assembly accuracy. For example, during the process of installing

the valve core into the valve body, the insertion depth and force

are strictly controlled to ensure sealing.

Inspection system: Equipped with high-precision pressure sensors

and flow sensors, the assembled expansion valve is inspected for

sealing performance and flow control performance. At the same time,

a visual inspection system is used to check for appearance defects.

If unqualified products are detected, they will be automatically

diverted to the repair area.

Control system: Adopting a PLC control system, operation and

monitoring are carried out through the touch screen human-machine

interface. It can display information such as the running status,

production progress, and quality data of the production line in

real time. And program adjustments and parameter settings can be

made according to different models of expansion valves.

| Cycle time | 12 s/pc |

| Defective rate | below 0.5% |

| Processes | laser welding |

| automatic tightening | |

| automatic press-fit | |

| visual detection | |

| laser marking | |

| O-ring automatic assembly | |

| automatic feeding | |

| Features | Fully automatic production w/o any worker |

| Real-time monitoring | |

| A level traceability throughout whole line |

Automotive (electric vehicle) automation solution

● Power system assembly automation solution

● Chassis system assembly automation solution

● Automotive electronics assembly automation solution

● Body and interior assembly solution

|